INDUCTION FORMING

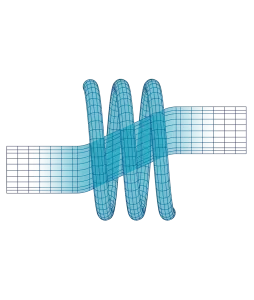

Induction forming is a manufacturing process that uses electromagnetic induction to heat conductive materials (typically metals) for shaping, bending, or joining. By passing an alternating current through a copper induction coil, a changing magnetic field is generated. This field induces eddy currents within the metal workpiece, causing it to heat up resistively. The localized heating allows precise control over the material’s temperature, making it malleable for forming operations such as bending, pressing, or welding.

Induction Forming

is a technology that utilizes the principle of electromagnetic induction to shape objects. Here is an introduction covering its principle, advantages, and applications:

is a technology that utilizes the principle of electromagnetic induction to shape objects. Here is an introduction covering its principle, advantages, and applications:

Principle

When an alternating current passes through an induction coil, an alternating magnetic field is generated. Metallic materials placed within this magnetic field induce eddy currents due to electromagnetic induction. As these eddy currents flow through the metal, they generate heat, causing the material to soften at a specific temperature. Subsequently, with the application of external force or through interaction with a specialized mold, the material undergoes plastic deformation, thereby altering its shape.

When an alternating current passes through an induction coil, an alternating magnetic field is generated. Metallic materials placed within this magnetic field induce eddy currents due to electromagnetic induction. As these eddy currents flow through the metal, they generate heat, causing the material to soften at a specific temperature. Subsequently, with the application of external force or through interaction with a specialized mold, the material undergoes plastic deformation, thereby altering its shape.

Advantages

- Precision Control: This method allows for accurate regulation of both the heating temperature and the shaping process, enabling the fabrication of intricate shapes to meet diverse design specifications.

- High Efficiency: Inductive heating rapidly raises the metal to the required shaping temperature, significantly enhancing production efficiency.

- Minimal Impact on Material Properties: Thanks to the short heating duration, the internal structure and properties of the metal remain largely unaffected, preserving its original characteristics.

- Environmental Friendliness and Energy Conservation: Compared to traditional heating and shaping techniques, inductive shaping offers higher energy efficiency and produces fewer pollutants, aligning with sustainable manufacturing practices.

Applications

- Metal Fabrication: Widely employed in mechanical manufacturing to produce complex components, such as specialized aerospace metal structures and automotive engine crankshafts.

- Electronic Device Manufacturing: Used for shaping metallic casings of electronic components, ensuring they meet structural and thermal management requirements.

- Medical Device Production: Applied in the fabrication of medical components with precise shape and dimensional specifications, including orthopedic implants.