Quenching and Tempering System

-

Quenching and Tempering System

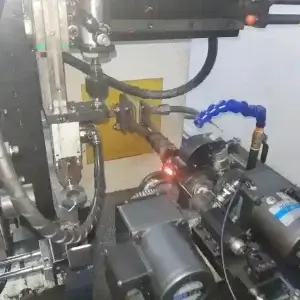

Camshaft Induction Hardening Machine

-

Quenching and Tempering System

Drill Stem Quenching and Tempering System

-

Quenching and Tempering System

Automatic Concrete Pump Pipe Induction Quenching System

-

Quenching and Tempering System

Circular Tube,steel Tube,drill Pipe Quenching And Tempering Heat Treatment Production Line

-

Quenching and Tempering System

Engine Valve Stem Induction Quenching System

-

Quenching and Tempering System

Induction Hardening Machine

-

Quenching and Tempering System

Induction Heating Ball Head Quenching Machine

-

Quenching and Tempering System

Inner Hole Induction Hardening Machine

-

Quenching and Tempering System

Quenching the inner wall of concrete pump pipe

-

Quenching and Tempering System

Roll Induction Quenching System

-

Quenching and Tempering System

slewing bearing induction quenching machine

-

Quenching and Tempering System

Wind Turbine Bolt Induction Quenching and Tempering System