30KW portable and small induction brazing machine

DSP digital intelligent power supply parameters

|

Type |

XZG-30SCN |

|

Input voltage |

380v/3 phase/50 hz |

|

Rated power (standard configuration) |

30KW |

|

Power regulation range |

5%-100%(Digital regulation) |

|

power control accuracy |

±0.5% |

|

Oscillating frequency |

20-50kHz |

|

Cable length |

4m |

|

Power Factor |

≥97% |

|

Work patter |

5%-100%(Digital regulation) |

|

Control core |

High performance dsp processor |

|

Controlling means |

Internal control and remote control arbitrary switching |

|

Operation interface |

Industrial touch screen+ button |

|

Communication interface |

RS485 |

|

Cooling method |

Combination of forced water cooling |

|

Machine size |

810*785*1275mm |

|

Line hanger size |

Height 2260mm cross arm length 2300mm |

|

Industrial chiller nominal cooling capacity |

4446kcal/h |

|

Industrial chiller Total input power |

2.18kw |

Touch screen version introduction

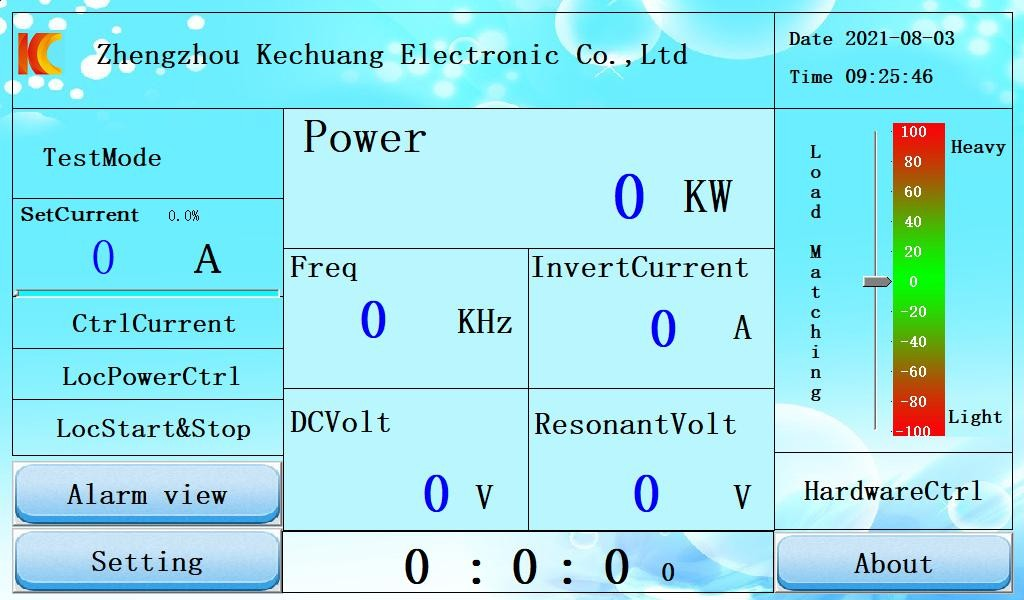

(1)The main interface displays the power percentage setting, heating voltage, heating current, heating power, heating frequency, working status, and load

matching indicating the power value that the current load can output, etc.

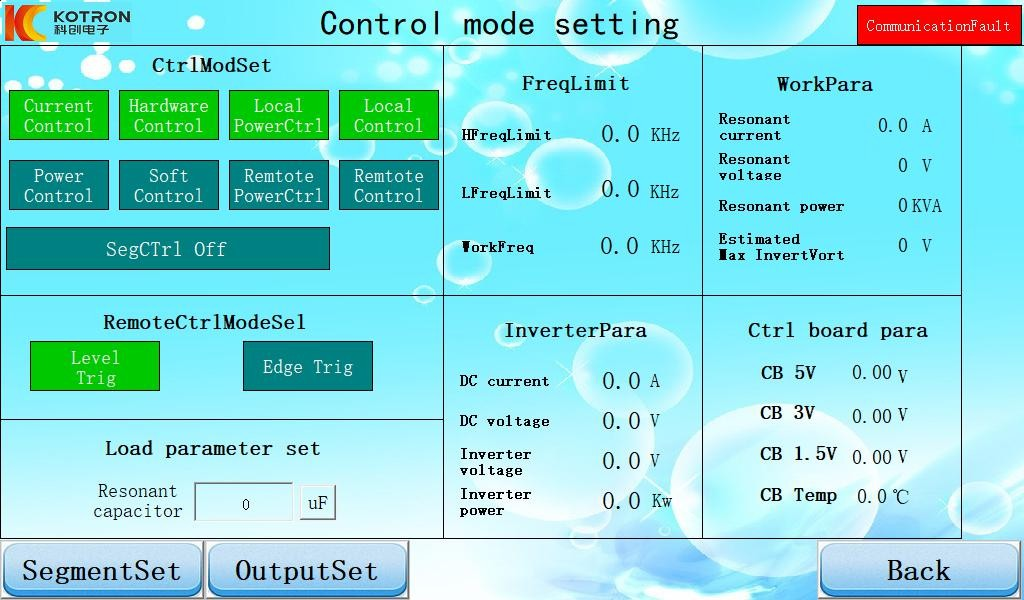

( 2 ) Control mode can be selected on the parameter setting interface, including constant current/constant power control;Hardware control/software control;Power internal control/power remote control, etc.It can also display inverter parameters, frequency limit parameters, load parameters, resonant capacitor parameters, remote control mode and main control operating environment parameters, including working voltage of 5V, 3V and 1.5v, motherboard temperature and other data.

( 3 ) Interface for comprehensive recording of energy, temperature and equipment status

The interface temperature control and record need the support function of infrared thermometer temperature acquisition

This optional advanced function has the function of real-time monitoring the energy of the heated workpiece.

It has alarm function of over or under energy

With historical query function

The events occurred in the operation results, including operation, data parameters, failure, alarm, product batch, personnel number, etc., shall be recorded effectively

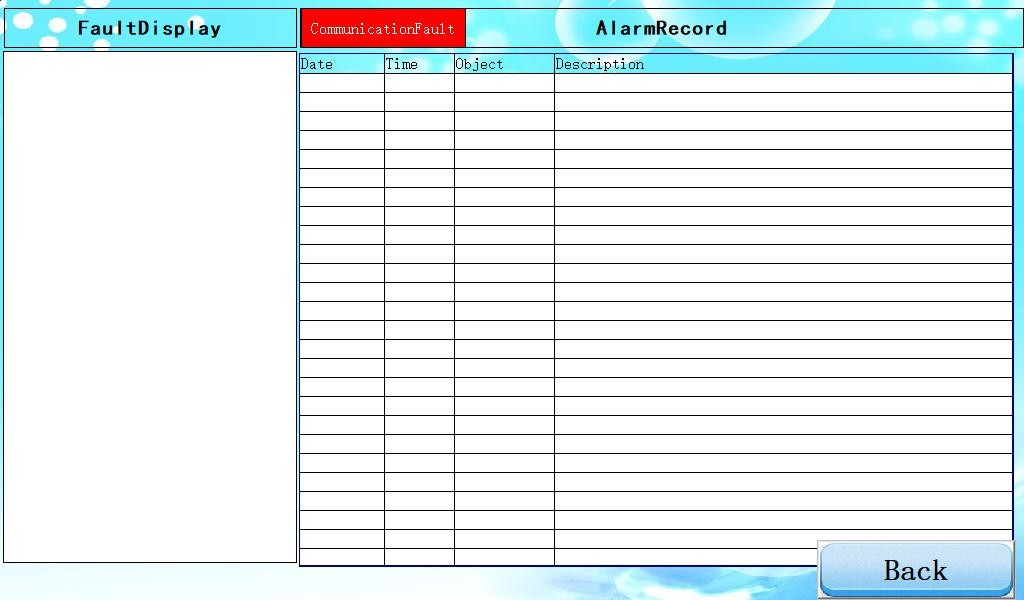

(4)Alarm view interface

This interface has “fault display area”, “alarm record” and return button.

Fault display area:This area displays real-time faults. After troubleshooting, press the reset button on the panel and corresponding faults will disappear from this area

The alarm record:This area is the historical fault record and view area, which will record the name, time and alarm description of the previous fault alarm, so as to facilitate the view and analysis of the cause of the fault.The equipment has self-diagnosis function, and the customer can judge the fault location through the alarm description.