Automobile anti-collision beam pipe heat treatment production line

Automobile anti-collision beam pipe heat treatment production line

This steel pipe heat treatment production line has dual-channel operation, which can be operated under centralized control or controlled independently by separate channels, making operation and conversion convenient.

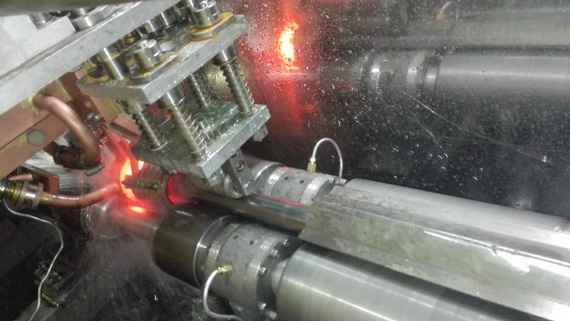

After the “tube products” are manually loaded and loaded, the loading table sends the workpieces to the production line conveyor belt, and the production line automatically completes the smooth transportation, rotation, heating-cooling (quenching), transportation, heating (tempering), and cooling of the workpieces. , unloading and other functions, no manual operation is required during the process (after the production line is adjusted), it is a fully automatic rigid tube quenching and tempering production line.

The quenching coolant automatically filters and circulates and has functions such as alarm or shutdown for over-operating conditions (such as overload, over-temperature, workpiece loss, failure).

What is the process flow of automobile anti-collision beam pipe heat treatment production line?

This steel pipe heat treatment production line has dual-channel operation, which can be controlled centrally or controlled independently by separate channels, making operation and conversion convenient.

After the "tube products" are manually loaded and loaded, the loading table sends the workpieces to the production line conveyor belt, and the production line automatically completes the smooth transportation, rotation, heating-cooling (quenching), transportation, heating (tempering), and cooling of the workpieces. , unloading and other functions, no manual operation is required during the process (after the production line is adjusted), it is a fully automatic steel pipe quenching and tempering production line.

The quenching coolant automatically filters and circulates and has functions such as alarm or shutdown for over-operating conditions (such as overload, over-temperature, workpiece loss, failure).

Production line introduction:

- Production speed: 6m-8m/min

- All mechanical rotation and transmission parts of the equipment should be flexible and reliable. The noise and heat generated by each component during movement should meet the product accuracy and national mechanical equipment industry standards. Each equipment and components meet the service life specified by the industry;

- All strong and weak electrical components and accessories should be safe and durable, and fully comply with relevant national technical standards;

- The production line has a one-click quick start working mode, and the operation panel display screen and related instruments (interfaces) have "human-machine dialogue" and adopt Chinese interfaces.

- It has the function of integrated operation or split operation of the "double station" of the production line, and also has the function of split operation of each module equipment;

- The production line has alarm or shutdown functions for each module's over-operating conditions (such as overload, over-temperature, workpiece loss, failure);

- The production line has the "intermittent quenching" function, and the control error is no more than 5mm;

- The production line is equipped with maintenance sockets and lighting. The external power cable routing is required to be reasonable and regular, and the cable (or copper bar) entrance is located at the bottom (or top) of the power supply;

- The appearance of the production line should be beautiful in design, adopt a "box-type" structure, and meet the requirements of heat dissipation and convenient maintenance. The color of the equipment shall be based on the color plate provided by the manufacturer (except for safety signs);

- After the entire production line is put into operation, there will be no leakage (electricity, gas, quenching fluid, coolant, oil), etc. Each pipeline will clearly display the liquid and gas flow direction signs, and the inlet and outlet pipes will use quick head changes for easy connection; secondary cooling All water pipes should be equipped with pressure gauges and temperature gauges to monitor water pressure and temperature;

- The main pipeline of the power supply and water-cooling part is made of copper pipes to reduce the generation of scale. All water pipe connections use 3/8 copper triple quick connectors to facilitate maintenance.

- The design, manufacturing, and installation of the production line should comply with national and industry regulations, and must meet safety production requirements. If there are safety hazards, safety protection devices must be added, and precautions must be highlighted.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.