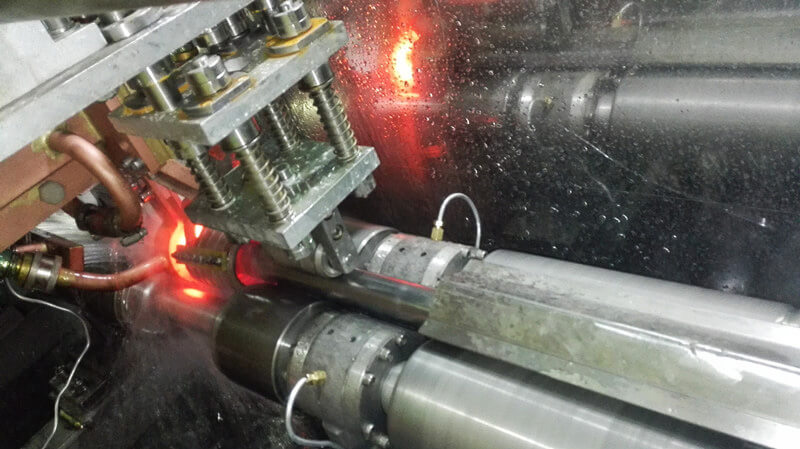

Collision-proof beam pipe heat treatment line

document.getElementById (“movie”).style.height=document.getElementById (“movie”).scrollWidth*0.56+”px”

The steel pipe heat treatment line has dual channel operation, can be controlled centrally, and can be operated independently by separate channels, which is convenient for operation and conversion.

After “pipe product” is put into the production line by manual centralization, the workpiece is fed into the conveyor belt of production line, and the smooth conveying, rotation, heating – cooling (quenching), conveying, heating (tempering), cooling, unloading and so on are completed automatically by the production line.

No manual operation is needed in the process (after adjusting the production line), it belongs to the automatic steel pipe quenching and tempering production line.

Introduction of Heat treatment Line for Collision-proof Beam Pipe

Technological process

The steel pipe heat treatment line has dual channel operation, can be controlled centrally, and can be operated independently by separate channels, which is convenient for operation and conversion.

After “pipe product” is put into the production line by manual centralization, the workpiece is fed into the conveyor belt of production line, and the smooth conveying, rotation, heating – cooling (quenching), conveying, heating (tempering), cooling, unloading and so on are completed automatically by the production line.

No manual operation is needed in the process (after adjusting the production line), it belongs to the automatic steel pipe quenching and tempering production line.

Quenching coolant automatic filtration, circulation.

Introduction of production Line:

1. Work speed: 6m/min;

2. The equipment should be flexible and reliable in rotating and driving parts.The noise and heat generated by the parts and components in the movement accord with the precision of the products and the national standard of machinery and equipment industry.The service life of each equipment and parts is up to the specified service life of the industry;

3. Each strong, weak electrical components, should be safe and durable, fully in line with the relevant national technical standards;

4. Has the production line “double station” to operate in one body or the split operation function, simultaneously has the each module equipment split operation function;

5. Protect function: overrun conditions (such as overload, overtemperature, workpiece lost speed, failure) alarm or shutdown functions;

6. The production line has the function of “discontinuous quenching”, and the control error is not greater than 5mm.;

7. The production line shall be equipped with repair sockets and lights. External power cable wiring is required to be reasonable, regular, and the cable (or copper bar) inlet is located at the bottom (or top) of the power supply.;

8. The appearance of the production line should be beautiful, “box type” structure, and can meet the requirements of heat dissipation and maintenance convenience, equipment color according to the color plate provided by the supplier (except for safety identification);

9. No leakage (electricity, gas, quenching fluid, coolant, oil) after the operation of the whole production line,Each pipeline shows the liquid prominently, the airflow direction marks, the incoming and outgoing water pipe adopts the quick change joint, facilitates the connection;Pressure gauges and thermometers shall be installed in all water pipes for secondary cooling to monitor water pressure and water temperature;

10. The water cooling part of the power supply is made of copper pipe to reduce the formation of scale. All the water pipe connectors adopt 3 / 8 “copper triplex quick change connector, which is convenient for inspection and repair.”