Where can we use the Heat Treatment Technology?

Where can we use the Heat Treatment Technology?

Heat treatment technology is widely used in many fields, including automobile manufacturing, aerospace, energy, machinery manufacturing and electronics.

Automobile manufacturing: In automobile manufacturing, heat treatment technology is used to improve the hardness and strength of automobile parts, as well as the wear resistance and corrosion resistance of the whole vehicle. For example, surface quenching and chemical heat treatment of engine cylinder block, crankshaft and other parts to improve their wear resistance and corrosion resistance.

Aerospace: The aerospace field has very high requirements for material properties. Heat treatment technology is used to improve the high temperature performance and fatigue resistance of engine blades, turbine discs and other parts. This helps to improve the high temperature resistance of aircraft engines and the safety performance of aircraft.

Energy field: In the energy field, metal parts in equipment such as nuclear reactors and boilers also need to be heat treated on the surface to improve their corrosion resistance and fatigue resistance.

Machinery manufacturing: Gears, bearings and other parts in machinery manufacturing also need to be heat treated on the surface to improve their wear resistance and corrosion resistance.

Electronics industry: Integrated circuits, semiconductor devices, etc. in the electronics industry also need to be heat treated on the surface to improve their corrosion resistance and stability.

In addition, heat treatment technology is also used in many industries such as metal manufacturing and electronics industry. By changing the internal organizational structure of materials, the mechanical, physical and chemical properties of materials are improved, thereby meeting application needs in different fields.

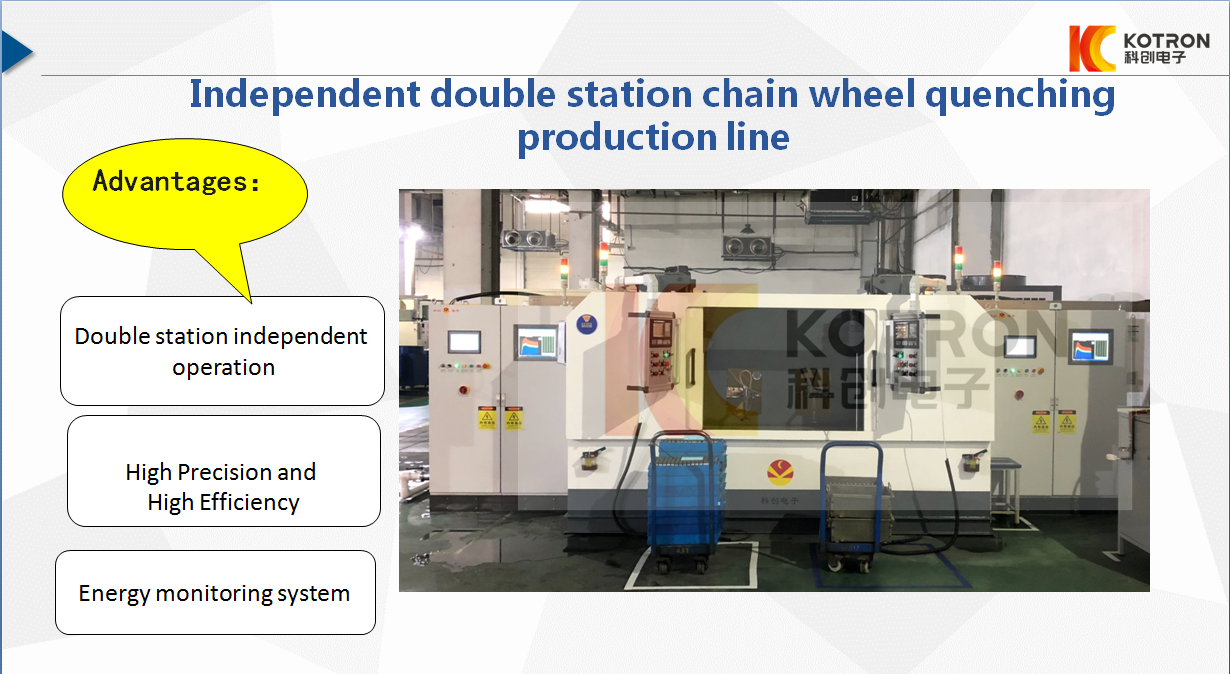

Sprocket and Gears High frequency induction heating machine quenching

TAG:  Sprocket Quenching