The Advantages of Induction Brazing/soldering Application

The advantages of High frequency induction heating machine brazing/soldering Application

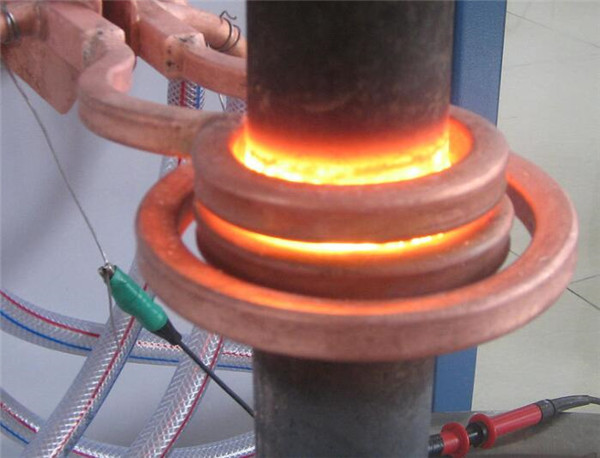

Induction heating has proven to be a valuable aid in the joining process for many reasons. Rapid heading and precise heat control offers the possibility of localized heating of high strength components without significantly changing the material properties. It also allows for the brazing of difficult materials such as aluminum and sequential, multi-alloy brazing and soldering of close proximity joints.

Induction heating in brazing and soldering applications is readily adaptable to production line methods, permitting strategic arrangement of the equipment in an assembly line, and if necessary, heating by remote control. Frequently, induction brazing and soldering permits a reduction in the required number of part fixtures, with the minimal heating of the fixtures increasing life span and maintaining accuracy in alignment of the components to be joined. Since operators need not guide the induction heating source, both hands are left free to prepare assemblies for joining.

Kechuang induction brazing equipment delivers quality, consistency, configurable throughput, and quick change-over tooling for various production needs. The Kechuang induction brazing and soldering product line offers standard solutions for brazing:

- Aluminum

- Copper

- Brass

- Stainless steel

- Carbide