2022 New Technology–Synchronous Dual Frequency Induction Heating Machine

2022 New Technology–Frequency Mixing Induction Heating Machine

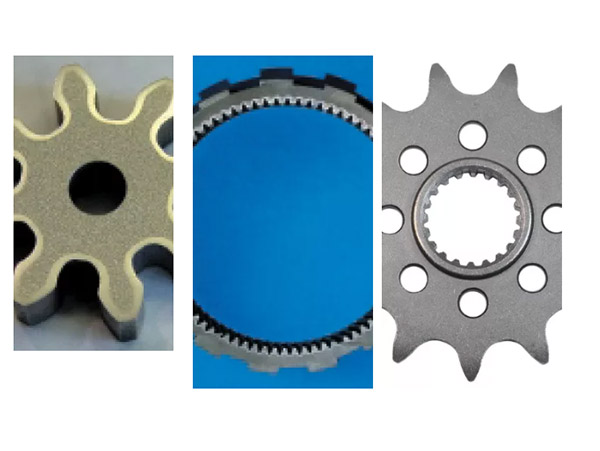

For Heating, Hardening and Quenching Heat Treatment.

#induction forging machine #induction forging equipment #metal forging

Power range and working frequency of hybrid dual-frequency power supply:

1-20 KHZ low frequency

High frequency: 20-200 KHZ

Low frequency power: 50KW-1000KW

Hf power: 30KW-300KW

Features and working frequency of mixed-frequency power supply:

Medium and high-frequency output heating simultaneously

Medium and high-frequencies can be used separately

Medium frequency and high-frequency power arbitrary adjustment

Medium frequency and high-frequency heating time arbitrary control

DSP high speed processor, fast control

The hardened layer has good imitation effect

Fast heating speed, small deformation

Almost no oxidation

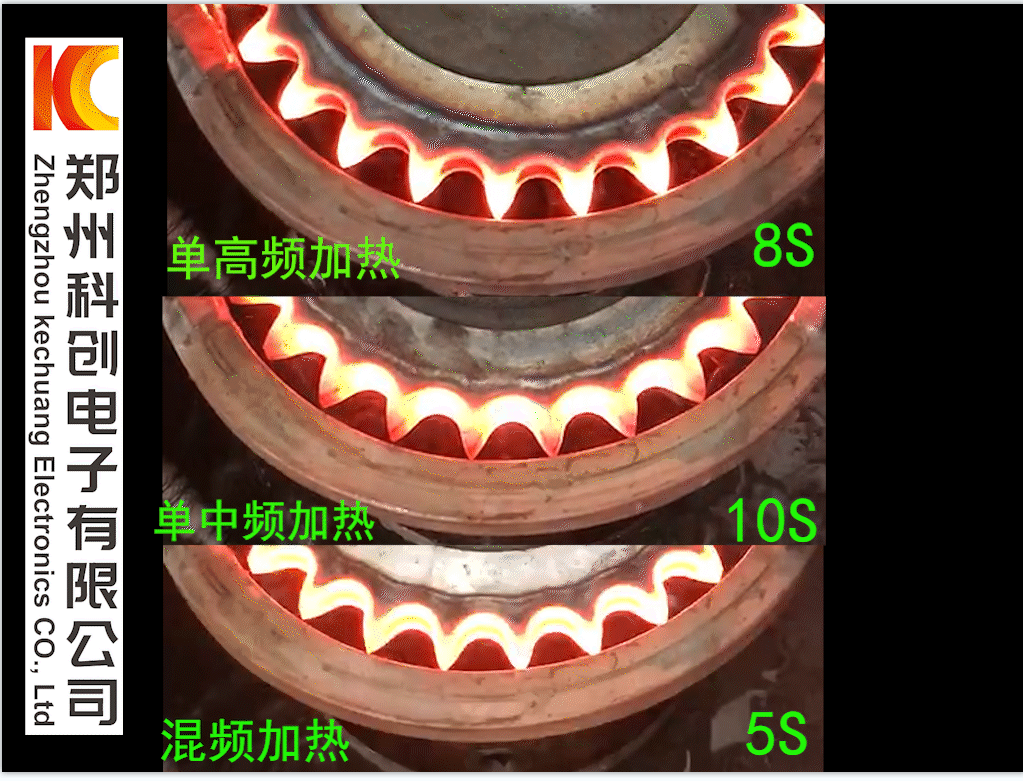

Synchronous Dual Frequency Heating Comparison

Power range and working frequency of hybrid dual-frequency power supply:

1-20 KHZ low frequency

High frequency: 20-200 KHZ

Low frequency power: 50KW-1000KW

Hf power: 30KW-300KW

Why use a Synchronous Dual Frequency(medium-frequency and high-frequency)Induction Heating Machine?

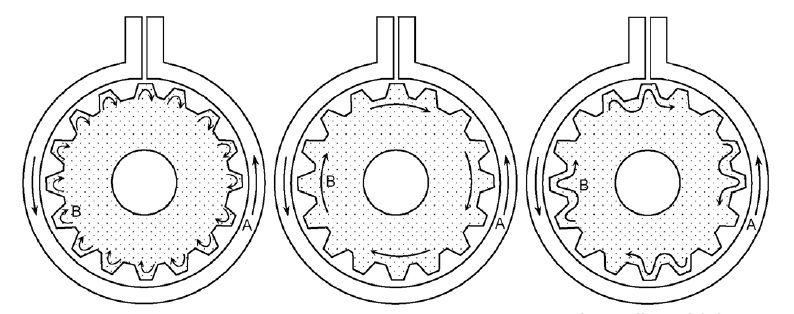

Synchronous Dual Frequency (dual-frequency) power supply refers to the induction heating power supply that can output one or two operating frequencies in the same induction coil at any time.

Two kinds of working frequency can be determined according to the process requirements, heating time and heating power can be adjusted arbitrarily, can run a certain frequency alone, can also run two kinds of frequency at the same time.

TAG: inductionheatingmachine inductionheater inductionfurnace inductionhardening inductionquenching hardening quenching heating

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.