30KW all-in-one induction brazing machine

Why Choose our 30KW all-in-one portable induction brazing machine?

30 KW all in one High frequency induction heating machine brazing machine with 4 meter long Coaxial transformer for copper pipes welding of Air Conditioner.

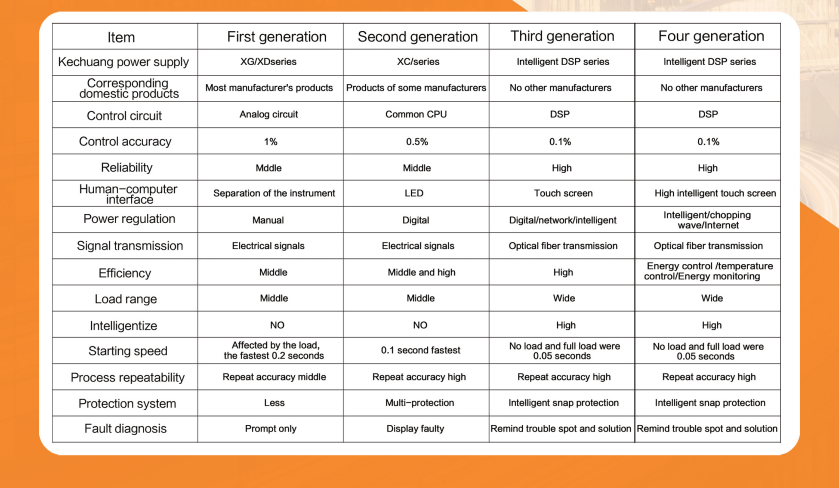

1. DSP induction heating power supply is adopted, and the main inverter circuit is controlled separately.

2. The intelligent digital induction heating power supply has a high-speed core processor of 100 megabytes, which can calculate and process all digital signals.

3. The signal Uses optical fiber transmission, in the transmission process, the loss of the signal is small, no error signal without distortion, enhance the stability of the control circuit.

4. DSP core control board can be extended up to 12 fiber signals.

What's included?

1) 30kw induction heating power supply

2) Industrial chiller/ Water cooling system

3) 4m Coaxial transformer cable(4m HHT)

4) Line hanger

5) 1pc induction coil

Which industries of the induction brazing machines can be used?

Induction welding

All kinds of turning tool, woodworking tool, brazing tip, saw blade saw tooth, steel pipe, copper pipe welding, the same kind of metal welding.

Widely used among the manufacturers of Air Conditioners and refrigerators.

Induction brazing is used in the tube and pipe

industry for the welding of stainless steel

(magnetic and non-magnetic), aluminium, low-carbon

and high-strength low-alloy steels and many

other conductive materials.

How to operate the Induction welding machine?

Power inverter parameters: display the dc current, dc voltage, inverter power and resonant voltage when the equipment is working.

Main control board parameters: display the motherboard voltage and motherboard temperature, easy to view the motherboard working status.

Used to select the input mode selection when the remote control device starts and stops;

Click the section heating setting button to enter the section heating setting interface.

What's the main Technical Parameters of induction brazing machine?

1) Rated input:three - phase four - wire(earth wire 30mm²),380V±5%

2) Power supply frequency:50/60Hz

3) Rated output: 5~30kW;

4) output frequency:20~40kHz;

5) Output power factor:≥98%

6) Power output range:5%~100%

7) working form :Suitable for intermittent and long term work;

8) Power supply cooling water pressure and flow:0.15Mpa~0.3Mpa,3T/h;

9) Cooling water temperature:25℃~35℃

10) Ambient temperature:+5℃ ~ +45℃

-

30KW all-in-one induction brazing machine

30 KW all in one induction brazing machine with 4 meter long...

-

Portable Induction Heating Machine

The intelligent digital induction heating power supply has a high-speed core processor of 100 megabytes, which can calculate and process all digital signals.

-

Tool Shrinking Machine

Tool Shrinking Machine

-

Analog Circuit Induction Heater

Power: 25-120KW Oscillating frequency: 10-80KHZ Input voltage 3 phase 380V 50/60Hz Water pressure: 0.15-0.3Mpa

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.