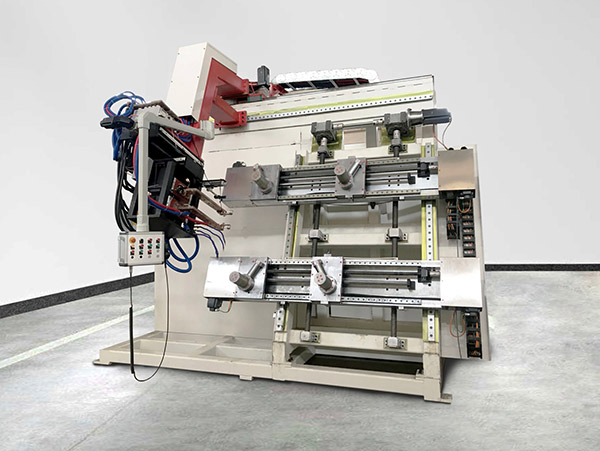

Inclined vertical raceway CNC quenching machine tool

Inclined vertical raceway CNC quenching machine tool

The inclined vertical raceway CNC quenching machine tool has manual operation and fully automatic operation functions. It is suitable for single-piece and batch parts production. It has functions such as continuous quenching and segmented simultaneous quenching. It is mainly used for large-scale slewing bearings, raceways, and inner channels. , Scanning quenching of ring-shaped parts such as outer channels. It is widely used in the field of induction heat treatment in wind power slewing supports, engineering machinery, and machine tool industries. It has reasonable structure, complete functions and convenient installation and debugging.

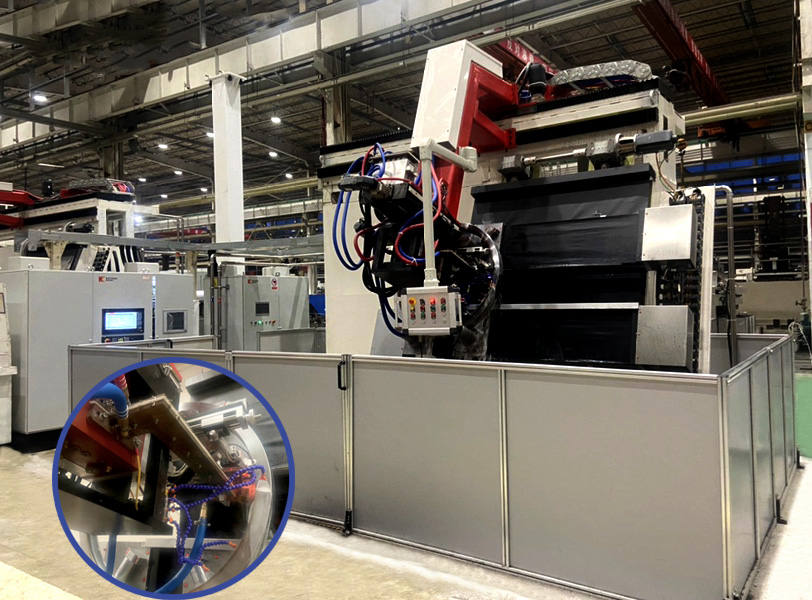

It has two induction heating output heads that can work simultaneously and in a time-sharing manner to speed up work efficiency. The layout of the equipment station is convenient and compact, making it easy to connect to other production lines to achieve linkage and full automation.

Structural features

The quenching machine tool adopts an inclined vertical type, with an angle of 70 degrees to the horizontal plane, and a steel frame welded structure. It adopts double beam structure and four-point positioning method, and each has two rollers to support the workpiece in two ways: supporting type and hanging type. The machine tool has four identical rollers. After adjustment, during quenching, the upper and lower beams each have two rollers. The left roller is fixed and the right roller can be adjusted left and right according to the diameter of the ring gear raceway. The upper and lower beams move in opposite directions at the same speed at the same time. , to adapt to the quenching needs of ring gear raceways of different diameters.

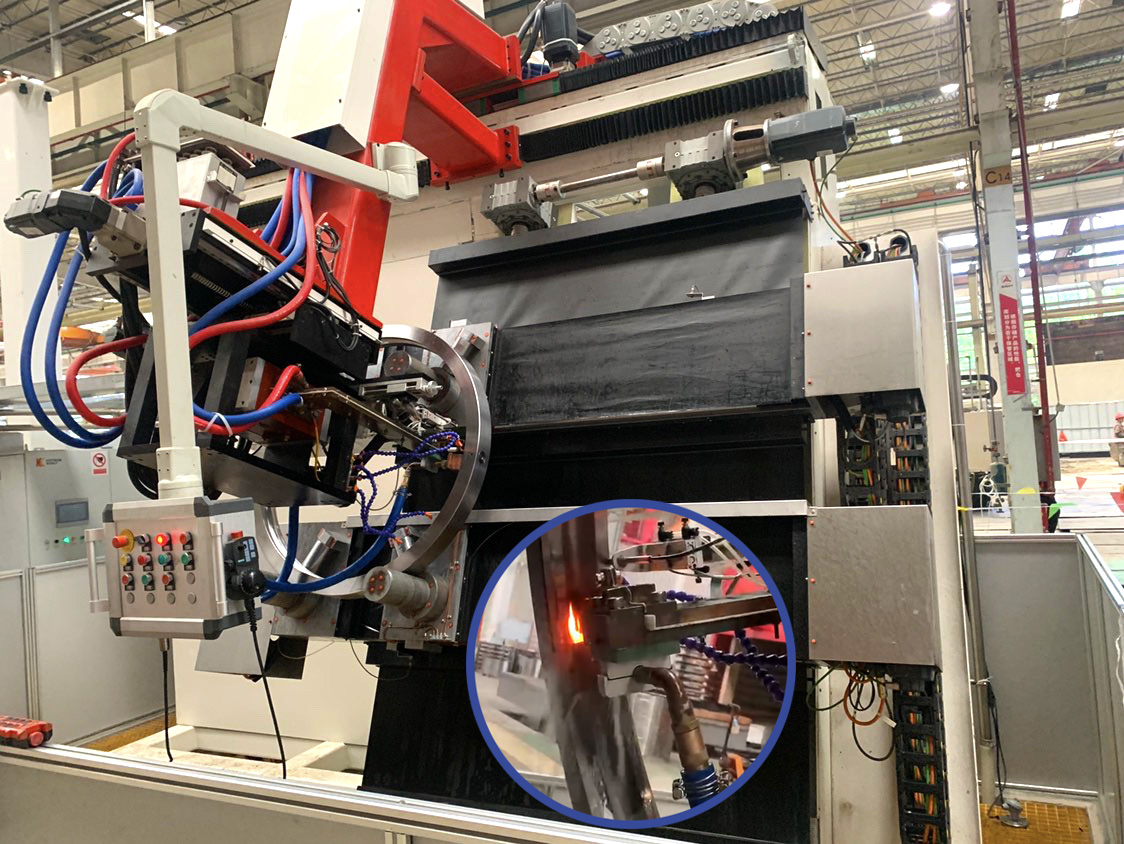

The workpiece is placed at an angle, and through the 840DSL system, 2 servo motors realize two-dimensional tracking of the induction coil and the quenching surface, 2 servo motors realize the roller rotation, and 1 servo motor realizes X-direction feed, realizing continuous scanning and quenching of the raceway. The Siemens system can be used to control and set the width of the soft belt and the quenching gap.

The cross slide carries two heating loads, a set of two-dimensional tracking, and a quenching liquid spray system. Based on the main heating load, the preheating load and tracking system can be manually fine-tuned in the front, rear, left and right two-dimensional directions; manual operation is added The platform, located 1 meter away from the load, is equipped with operations such as power addition and subtraction, liquid spray cut-off and connection, heating cut-off and connection, and displacement handwheel, making it easy for the operator to adjust the product model. After adjustment, the system automatically records it and no adjustment will be required for subsequent mass production.

How quenching machine tools work?

The quenching machine tool has two working modes:

Hanging type: The roller on the upper beam is used as the driving wheel. The servo motor drives the roller to rotate. The roller drives the slewing bearing to rotate. The workpiece raceway is continuously quenched. The induction coil is controlled by the CNC and servo motor through the floating mechanism in the radial and radial direction of the cross slide. Automatic axial tracking.

Support type: The position of the left roller is fixed, and the roller on the cross beam is driven by a servo motor; during operation, the roller drives the workpiece to rotate, and the workpiece is continuously quenched. The induction coil is controlled by the CNC and servo motor through the floating mechanism to automatically track the cross slide in the radial and axial directions.

The upper and lower beams of the quenching machine can be driven up and down by the motor to drive the screw rod to adapt to the quenching of workpieces with different diameters. There are scales on both sides of the guide roller and the cross beam to improve the adjustment efficiency and accuracy. The positions of the four rollers are determined according to the workpiece diameter φ1000mm ~ φ3000mm.

The surface of the roller is patterned and heat treated.

Load part:

It adopts a thin quenching transformer and is made of imported silicon steel magnetic core. It has small magnetic leakage, high efficiency and small self-loss, and overcomes the problem of serious heat generation during continuous operation. Achieve lightweight quenching equipment. The water circuit part adopts a fully external connection method and uses quick-change joints. The connection from the power supply to the load uses flexible cables.

Machine tool protection:

The control system is designed with multiple machine tool action protection devices (or programs) and other protections to ensure the safety of operation and prevent losses caused by machine tool action failure or misoperation.

Protection against rotation of the workpiece during quenching:

A roller is installed on the carriage of the machine tool. The rotation of the workpiece will drive the roller to rotate. The roller drives the encoder to rotate and outputs pulses to the control system. The minimum speed can be set in the system. If it is lower than the set value, the system will alarm and stop. Heating to prevent the workpiece from abnormally stopping during the power heating process, causing the workpiece to be burned.

Induction coil protection against workpiece contact:

The equipment is equipped with a special circuit board to detect the contact current between the Induction coil and the workpiece, and quickly disconnects the power supply if it exceeds the set value. During the quenching tracking process, if an abnormality occurs, theInduction coil will touch the workpiece and the heating cannot be stopped quickly, which will cause local melting of the workpiece raceway.

The power supply has power and current monitoring functions. During the quenching process, if the voltage or current is abnormal, it will automatically stop heating if it exceeds the set range, and send a signal to the quenching machine tool control system to stop quenching.

-

DSP80KW Portable Induction Welding Machine with HHT

DSP80KW Portable Induction Welding Machine with handheld transformer

-

Special induction power supply

-

High precision parallel resonance power supply

-

High precision series resonance Ultra high frequency/MF/super audio power supply

-

MF/super audio Universal series resonance power supply

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.