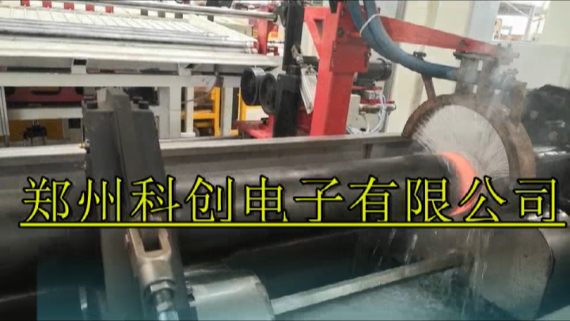

Concrete pump tube automatic quenching production line

1. XZZ-250SCN DSP digital High frequency induction heating machine heating power supply

2. KCZG-WS-3000 Induction quenching machine for conveying straight pipe

3. Industrial Chiller–Quenching fluid and power cooling

4. Plate heat exchanger and stainless steel tank with 2m³ water tank and contains 1.5KW water pump.

Quenching process flow

Using 250KW IGBT digital intelligent DSP High frequency induction heating machine heating power supply, frequency 5-20khz.

Double pipe quenching 250kW Induction heating power output is used to quench the inner wall, and the inner water spray is used to quench the inner wall.

According to the process demand, DSP power supply can be used for digital power distribution.

When the induction heating equipment is heating the pump pipe of different specifications, the output power of inductor can be set automatically according to the model of the workpiece and the control system of the machine tool.

The central control center has a variety of heating process implementation and automatic control program switching functions.

No manual intervention is needed to switch between different quenching processes.The induction quenching heating coil is equipped with a water spraying device.

Through the centralized control center program switching, the water spraying cooling process is implemented automatically for different workpiece models;

The running speed of the straight pipe of the production line is controlled by a fast high-power servo motor.

The designed air running speed is ≥3 m /min. When heating, the rotating speed is controlled by frequency conversion motor, supported by multistage supporting roller in the middle of straight pipe, which can meet the requirements of working procedure (including feeding and unloading) : 6min/ pc (3 meters), no soft belt, no thread.

|

Model |

XZZ-250SCN |

|

Type |

DSP digital induction heating power supply |

|

Rated Voltage |

AC380V,50Hz |

|

Rated power (Standard configuration) |

250KW |

|

Power regulating range |

Any adjustment within the range of 1%-100% |

|

Power control accuracy |

±0.2% |

|

output frequency |

5-20KHZ DSP adaptive frequency tracking |

|

Inverter power factor |

≥98% |

|

level of protection |

IP54 |

|

working mode |

Constant voltage, constant power with voltage regulator function |

|

core control |

High performance DSP processor TI |

|

Control Method |

Arbitrary switch between internal control and remote control |

|

Operation interface |

Industrial touch screen + button |

|

communication interface |

RS485 |

|

ambient temperature |

0-40℃ |

|

Ambient humidity |

≤90%RH |

|

altitude |

≤1000m |

|

Cooling mode |

Combination of forced water cooling and air conditioning |

Main technical parameters of quenching machine tool

|

|

|

|

Maximum turning diameter of workpiece(mm) |

150 |

|

maximum workpiece weight(Kg) |

200 |

|

|

≤±0.2 |

|

Workpiece rotation speed range(r/min) |

20~100 |

|

|

4.0 |

|

Quenching fluid flow |

≥300L/min |

|

Quenching fluid pressure |

|

|

|

≤30℃ |

Project Configuration

|

No. |

Item |

Model |

Qty |

Remark |

|

1 |

High frequency induction heating machine heating power supply |

XZZ-250SCN |

1 set |

DSP digital induction heating power supply |

|

2 |

Induction heating load |

1 set |

||

|

3 |

Main and auxiliary resonant cable |

1 set |

||

|

4 |

Quenching induction coil |

1set |

||

|

5 |

Induction quenching machine for conveying straight pipe |

KCZG-WS-3000 |

1 set |

|

|

6 |

Internal hole heating load moving platform |

1 set |

||

|

7 |

Industrial Chiller |

KCLD-20 |

1 set |

Quenching fluid and power cooling |

|

8 |

Plate heat exchanger + stainless steel tank |

|

1 set |

The water tank is 2m³ and contains 1.5KW water pump |

-

DSP80KW Portable Induction Welding Machine with HHT

DSP80KW Portable Induction Welding Machine with handheld transformer

-

Special induction power supply

-

High precision parallel resonance power supply

-

High precision series resonance Ultra high frequency/MF/super audio power supply

-

MF/super audio Universal series resonance power supply

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.