Standard intelligent High frequency induction heating machine heating power supply features

01

Save electricity

Full digital frequency tracking technology enables IGBT to work at all times zero open state, the inverter power factor always remains above 95%. The composite motherboard structure makes the whole inverter unit need not be absorbed back Road, inverter efficiency is greatly improved.

02

High control accuracy

High design resolution: control resolution up to 0.025% . Fast control speed: the control response speed is at High control accuracy the nanosecond level, namely 0.0000000000006 seconds.

03

Stability is good

High repetition accuracy: no power drift will occur in cumulative startup. Good anti-interference performance: the stability of temperature, humidity and power grid voltage is good, and the change will not affect the equipment.

04

The cost is low

It adopts non-control rectifier, inverter to adjust power, simple topology, under the condition of conventional heating, realize the characteristics of fewest devices and simple structure, and effectively control the cost of the whole machine.

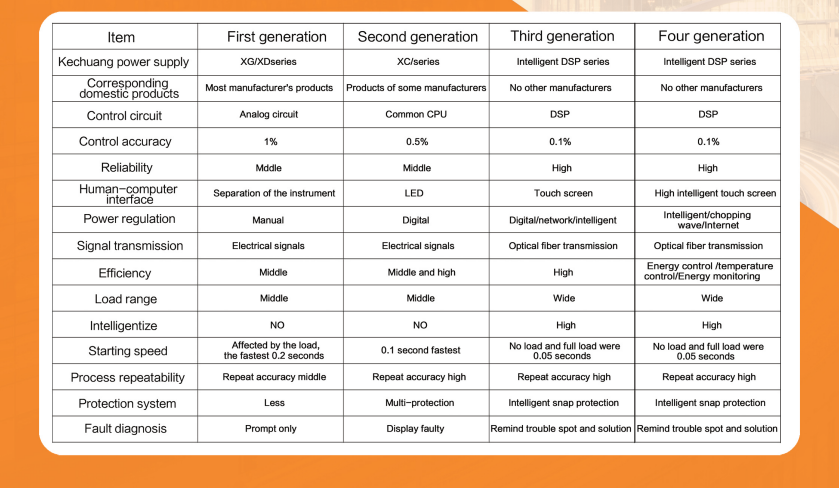

Standard intelligent High frequency induction heating machine heating power supply -Compared to traditional analog circuits

01

Good consistency

High repetition accuracy: no power drift will occur in cumulative startup. Good anti-interference performance: temperature, humidity, network voltage changes will not affect the equipment.

02

Long service life

Cabinet design life is long: fully sealed design, at the same time using strict anti-rust treatment, so that the cabinet life is much higher than similar products on the market. Long design life of the core components: the core components are all imported products, some of the components adopt military standards. The control circuit design is durable: the control circuit board is made of high quality PCB board, the control chip is up to the.

03

Low failure rate

The maintenance rate of new products under warranty is extremely low.

04

Good scalability

Abundant external interface and strong plasticity are the biggest characteristics of the intelligent induction heating power supply.

Standard intelligent induction heating power supply-Compared with other manufacturers of digital power supply

01

Adopt high speed DSP chip

It has extremely high anti-interference ability, and the running speed is 10 times of the traditional microprocessor, which effectively ensures the high performance and stability of the equipment.

02

Adopt aluminum - zinc plate imitation Rittal cabinet

Greatly improved the service life of the equipment cabinet, in addition to the imitation of the Rittal structure to make the equipment more beautiful.

03

The laminated motherboard is used to ensure the stability of the inverter

The laminated bus with patented technology can effectively reduce the distributed inductance on the dc bus, so as to reduce the working peak of the inverter and greatly improve the service life of the inverter.

04

Fiber optic transmission

Completely solve the induction heating power vulnerable to electromagnetic interference problem, to ensure the consistency and stability of signal transmission.