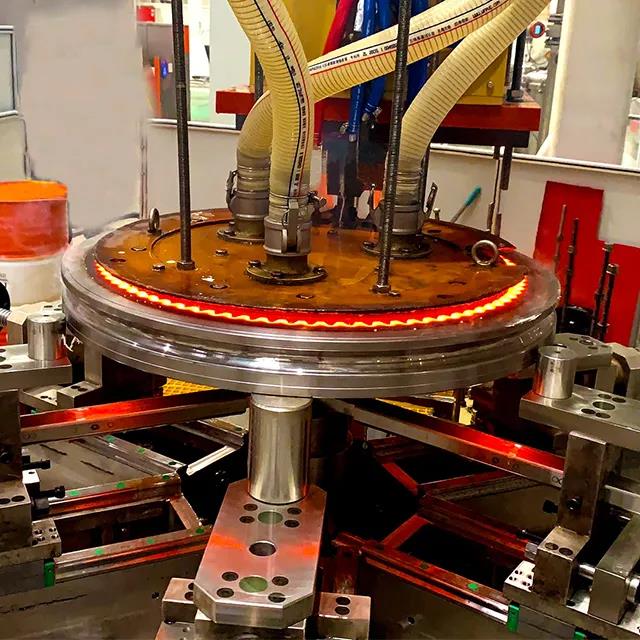

Slewing Bearings Induction Quenching Machine

2024-03-22

The cantilever type whole-tooth CNC hardening machine has manual and fully automatic operation functions. It is suitable for the production of single and batch parts. It has the functions of continuous quenching and simultaneous quenching. It is mainly used for large slewing bearings, internal teeth, external teeth, tooth surfaces, etc. The overall quenching of ring parts is also suitable for High frequency induction heating machine quenching of wheels, rings and plane parts. It is widely used in induction heat treatment of wind power, automobile, engineering machinery, and machine tool industries. Reasonable structure, complete functions, convenient installation and debugging.

Structural features:

1. The machine tool structure adopts the cantilever + rotary table method, the beam carries the power load, and can move up and down, left and right, and at the same time quenching the tooth surface of the workpiece.

2. The workpiece is placed horizontally, through the 840DSL system, the load sliding table and the mobile numerical control system realize the alignment of the inductor and the quenching surface to realize the overall quenching of the workpiece.

3. The Siemens system can achieve accurate clearance control, and the accuracy deviation is less than 0.2mm. The whole set of equipment includes a set of beam and work cantilever, a set of heating load, and a set of integrated induction quenching liquid spray sensor.

4. Set up manual operation interface, flexible cord connection, which can be extended to a distance of 1 meter from the load, with power addition and reduction, spray cutting, access, heating removal, access, displacement handwheel and other operations, which are convenient for operators to adjust the product Model. After adjustment, the system automatically records, and subsequent mass production will not be adjusted.

Zhengzhou Kechuang Electronics Co., Ltd. was established in 2001. It is an early high-tech enterprise specializing in induction heating equipment and related complete sets of equipment in China. Based on IGBT induction heating power supplies, the company vigorously develops induction heating electromechanical products; and has successfully developed: complete sets of chain track equipment, sales Axle pin sleeve complete set of equipment, drive wheel, support wheel, slewing support channel, single tooth, complete tooth and other complete quenching equipment, wire heating complete equipment, automotive steering gear rack special complete quenching equipment, concrete pump tube inner wall quenching complete equipment , Double-sided ribbed steel heating complete set of equipment, alloy copper precision forging equipment, steel strip online quenching and tempering complete equipment, solar heat collecting tube baking complete equipment and other heat treatment equipment. Products are widely used in engineering machinery, machinery manufacturing, aerospace, petrochemical, metallurgy, microelectronics, light industry, electric power, scientific research and other fields.